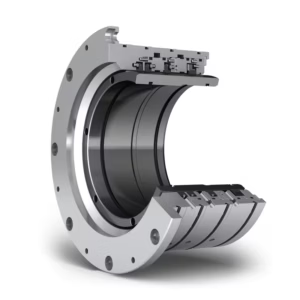

Kaydon engineers understand the demanding environments that challenge compressors in petroleum and natural gas service, and work with your team to provide the most reliable solution for seals and support systems within your budget. And when it comes time for overhauls Kaydon is ready to supply expert inspection and quick turnaround repairs.

Kaydon engineers understand the demanding environments that challenge compressors in petroleum and natural gas service, and work with your team to provide the most reliable solution for seals and support systems within your budget. And when it comes time for overhauls Kaydon is ready to supply expert inspection and quick turnaround repairs.

Contact Kaydon to learn how we’ve solved additional customer sealing issues, including:

Retrofits of refinery wet gas compressors from a labyrinth educator seal system to a Kaydon circumferential seal, eliminating all hazardous gas escaping to atmosphere without modification to compressor shaft or casing.

Upgrading of natural gas pipeline compressors from oil buffered seals to Kaydon dry gas seals and separation seals. Seal support systems and radial bearing upgrades permit ease of unattended operation and reduce venting of gas to atmosphere.

Use of gold plated process side bushings on oil seals in sour gas service or where gas compressors are flushed with caustic wash that will attack Babbitt. Kaydon has extended run times from less than one year to more than years, with the gold bushing still in like-new condition when seals are pulled for inspection.

Oil & Gas

Oil & Gas

For the Oil & Gas industry, up time is money, so the reliability of their equipment is key. Seals play an integral role in the overall reliability of process equipment, and one type of seal does not fit all. Few suppliers can provide the range of shaft seal products to fit the petroleum and natural gas industry’s need to optimize reliability as well as Kaydon. Dry gas seals, separation seals, and circumferential seals as well as oil buffered bushing, and mechanical seals are all available to fit specific needs.

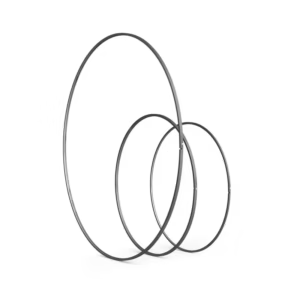

Piston Rings for General Industry

Piston Rings for General Industry

Kaydon Ring & Seals has developed many unique non-metallic ring solutions for a broad range of applications. Polytetrafluoroethylene (PTFE) rings with metallic energizing rings are used as secondary seals in carbon seal assemblies. PTFE rings filled with glass, bronze or carbon are applied in sealing applications including hydraulic cylinders and valves. Kaydon piston rings are used as primary seals in applications as diverse as cryogenic pumps and power transmissions. Specialty ring joints to minimize leakage or aid with installation and assembly are all available.

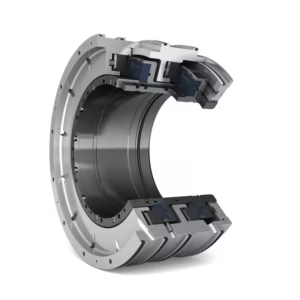

Aerospace/turbine carbon seals

Aerospace/turbine carbon seals

Kaydon Ring & Seal is a leading supplier of carbon seals used in turbine engines, actuators, auxiliary power units, environmental control units and high temperature valve applications for both military aerospace and commercial aircraft platforms. Decades of engineering, application and manufacturing expertise are behind every product shipped, and result in Kaydon Ring & Seal being a “go to” supplier for not only today’s program needs but also the newest engine programs.

Main shaft bearings seals

Kaydon Ring & Seal carbon seal designs are primarily utilized as main shaft bearing seals in aerospace and aircraft engine applications. Carbon face seals, carbon circumferential seals are commonly applied for these applications.

Aerospace turbine engine shaft seals are engineered to seal the main shaft and oil sump for more efficient and environmentally sustainable operation. Kaydon Ring & Seal manufactures carbon seals and circumferential seals which set quality and performance standards for many commercial and military aerospace engines. Kaydon Ring & Seal lift seal designs have shown clear performance advantages in reducing heat and wear throughout the engine flight cycle.

Kaydon Ring & Seal shaft seal runners, spacers and support structures simplify the supply of associated seal components and assure the proper interface of mating components.

Aerospace industry quality

Kaydon Ring & Seal is known for consistently high quality, using continuous improvement and Six Sigma methodologies to achieve ever-higher levels of performance. Kaydon Ring & Seal’s internal quality programs and processes are supported with approvals from; ISO9001, AS9100D and NADCAP process approvals, as well as numerous individual process approvals from leading OEM customers.

Kaydon Ring & Seal carbon seals for aerospace applications:

- Aerospace face seals

- Aircraft oil bearing Sump seals

- Turbine engine shaft seals

- Actuator seals

- Auxiliary power unit (APU) seals

- Environmental control unit (ECU, ECS) seals

- High temperature valve application seals

- Military aerospace engine seals

- Commercial aircraft engine seals