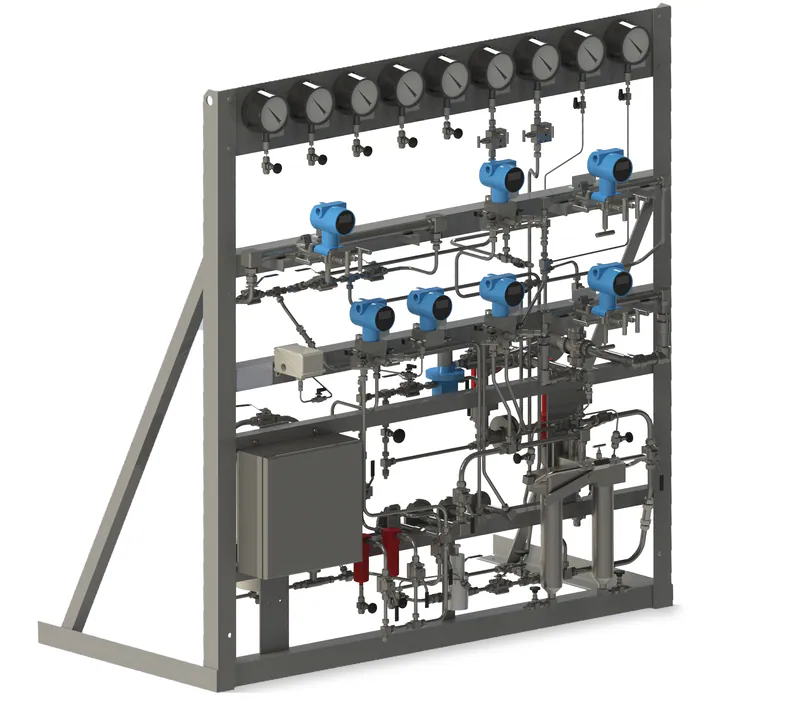

Gas Control Systems

Each Kaydon control system is designed specifically for the application and budget. A system concept is developed with consideration for safety, piping and electrical regulations, and reliability requirements that will suit the particular needs of the application as well as the proper function of the seals. Concepts are transferred to P&ID drawings, general arrangement models, and electrical schematics that can be used to support final construction and site installation.

Upon assembly, each system is subjected to pneumatic testing of all gas lines and continuity testing of all instruments and transmitter signals to assure proper operation. The final product is delivered ready to install.

Features and Benefits

- Proper conditioning of seal gas to meet the requirements of the seals used

- Monitoring of seal performance and health

- Allows for remote operation of compressor

- Alarms and callouts for seal upset conditions

- Shutdown in the event of a catastrophic seal failure or seal loss of seal gas

- Coordination and integration with customer-preferred component suppliers

Applications

- Natural gas transmission

- Pipeline booster compressor shaft seals

- Natural gas and CO2 re-injection compressor shaft seals

- Natural gas processing plants

- Propane refrigeration, sales gas, raw gas, residue gas compressor shaft seals

- LNG refrigeration and boil-off compressor shaft seals

- Refinery

- Hydrogen recycle, platformer, reformer, wet gas, coker, alkylation, isomerization, flare gas recovery

- Petrochemical

- Ethylene, propylene, polypropylene, charge gas, propane refrigeration, iso-butane, ethylene oxide, styrene off-gas, low density polyethylene (LDPE), linear low density polyethylene (LLDPE), polyethylene, carbon monoxide, methanol, synthesis gas, ammonia refrigeration, acetylene, feed gas