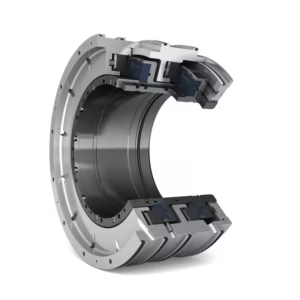

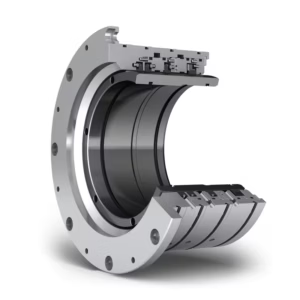

K-CBS Circumferential Barrier Seal

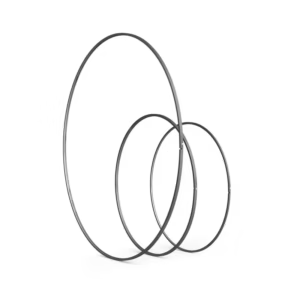

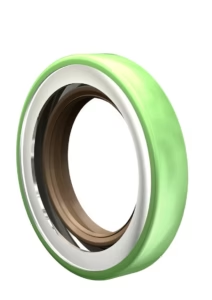

The K-CBS separation seal consists of segmented carbon rings that act as a wedge between the stationary housing and a hard-coated rotating shaft surface. The seals are buffered with gas at a pressure slightly higher than that of the cavities being separated. The seal rings are preloaded by a combination of radial garter springs and axial compression springs. Contact forces are minimized by pressure dams in both the side face and bore of each ring, which in turn minimizes wear and allows the seal rings to freely follow the movement of the shaft. The rings are designed with an initial overlapping clearance between segment ends. As the bore of the seals wear, the clearance decreases until the segment ends butt together. At this point, the ring is archbound and continues to function as a clearance seal, providing the same reliable performance.

Features and Benefits

- Prevents bearing oil contamination of dry gas seal

- Provides final protection against process gas escape in the event of dry gas seal failure with structural integrity of 800psi+ [55bar+]

- Controlled separation seal gas leakage of .1 scfm per inch diameter per seal ring at 15psig [1bar]

- Expected run time of 40,000hrs+ prior to archbound condition

- Compact size allows for retrofit of most labyrinth seals

- Specialty materials available for low-dewpoint gases

- Field rebuildable with Kaydon supplied carbon kits

- May be combined with K-DGS dry gas seal for single DRYPLEX™ cartridge assembly

- May be applied as main shaft seal in K-MRC configuration

Applications

- Natural gas transmission

- Pipeline booster compressor shaft seals

- CO2 re-injection and natural gas compressor shaft seals

- Natural gas processing plants

- Propane refrigeration, sales gas, raw gas, residue gas compressor shaft seals

- LNG boil-off and refrigeration compressor shaft seals

- Refinery

- Hydrogen recycle, platformer, reformer, wet gas, coker, alkylation, isomerization, flare gas recovery

- Petrochemical

- Ethylene, propylene, polypropylene, charge gas, propane refrigeration, iso-butane, ethylene oxide, styrene off-gas, low density polyethylene (LDPE), linear low density polyethylene (LLDPE), polyethylene, carbon monoxide, methanol, synthesis gas, ammonia refrigeration, acetylene, feed gas