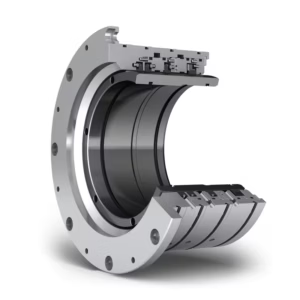

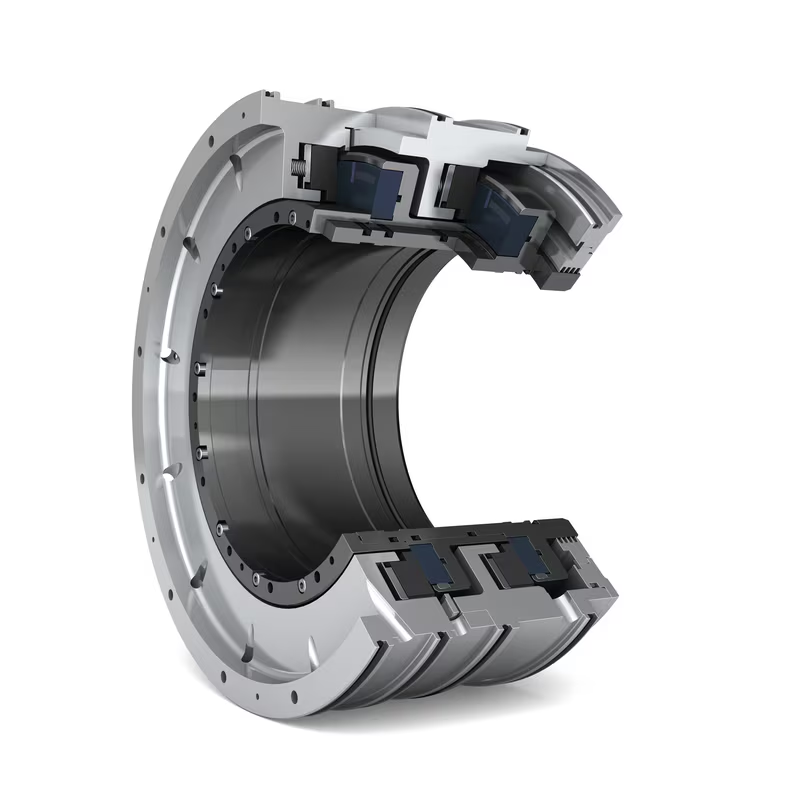

K-DGS Dry Gas Seal

Patented Tapered Lift Ramp Geometry

At the heart of every K-DGS is the lift ramp geometry to generate and maintain lift force and clearance between the rotating and stationary seal faces. Kaydon's patented Tapered Lift Ramp geometry causes an increase in velocity of the seal gas as it moves through the ramp, sweeping contamination away from the sealing faces.

Features and Benefits

- Lowest leaking gas seal type available for turbo machinery

- Various configurations are available to fit the application: tandem, tandem with intermediate labyrinth, single, double

- Patented Tapered Lift Ramp geometry generates lift with rotation and expels contamination

- Bi-directional seals are available to provide protection during reverse rotation, and to limit spares inventory Silicon carbide rotating seal faces are used as standard to increase durability during incidental contact caused during startups, shutdowns, and other transient conditions

- Factory leak tested at application speeds, pressures, and temperatures

- May be combined with K-CBS separation seal for single DRYPLEX™ cartridge assembly

Applications

- Natural gas transmission

- Pipeline booster compressor shaft seals

- Natural gas and CO2 re-injection compressor shaft seals Natural gas mid-stream processing plants

- Propane refrigeration, Ethylene refrigeration, Propylene refrigeration, sales gas, raw gas, treat gas,

- residue gas compressor shaft seals

- LNG refrigeration and boil-off compressor shaft seals Refinery

- Hydrogen recycle, platformer, reformer, hydrotreater, wet gas, coker, alkylation, isomerization, flare gas recovery

- Petrochemical

- Ethylene, propylene, polypropylene, charge gas, propane refrigeration, iso-butane, ethylene oxide, styrene off-gas, low density polyethylene (LDPE), linear low density polyethylene (LLDPE), polyethylene, carbon monoxide, methanol, synthesis gas, ammonia refrigeration, acetylene, feed gas