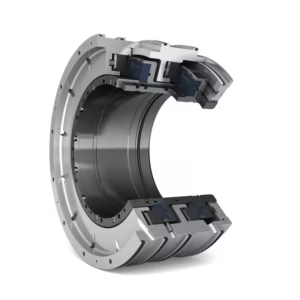

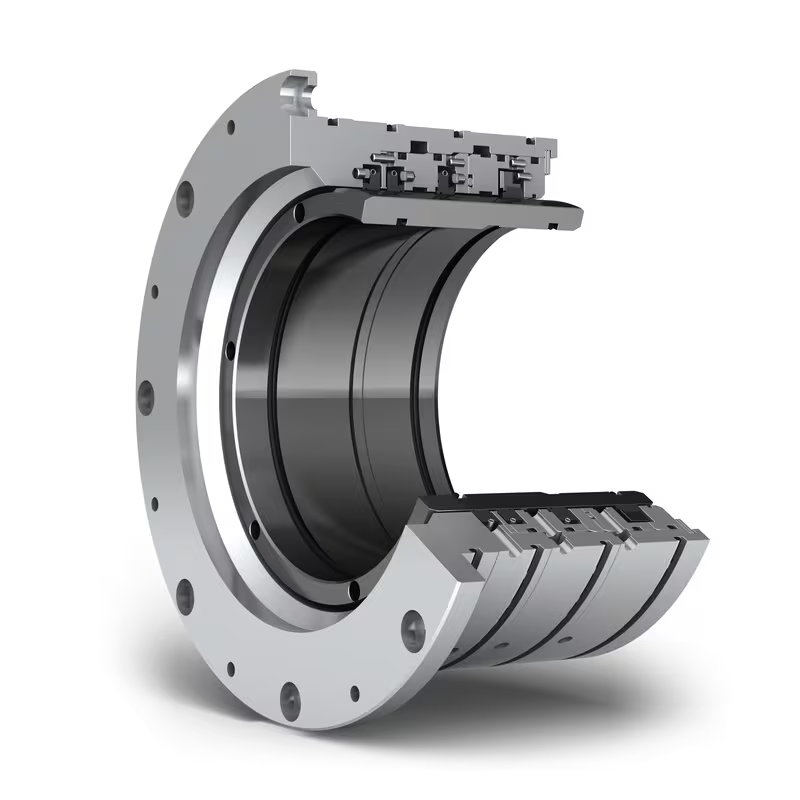

K-MRC Multi-ring Circumferential Gas Seal

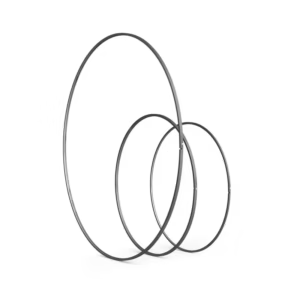

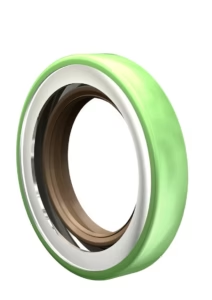

The K-MRC is a standalone, dual purpose main shaft seal that prevents process leakage from escaping through the equipment bearings while also preventing bearing oil migration into the process. The K-MRC utilizes segmented carbon seal rings that act as a wedge between a stationary housing and a hard-coated rotating shaft surface. The seals are buffered with gas at pressure slightly higher than the regions being separated. The seal rings are preloaded by a combination of radial garter springs and axial compression springs. Contact forces are minimized by pressure dams in both the side faces and bore of each ring, which in turn minimize wear, and allows the seal rings to freely follow the movement of the shaft. The rings are designed with an initial overlapping clearance between segment ends. As the bore of the seals wear, the clearance decreases until the segment ends butt together. At this point, the ring is arch bound and continues to function as a clearance seal, providing the same reliable performance.

Kaydon circumferential seals are extremely durable and do not have a catastrophic failure mode. They are able to experience solid and liquid contamination with only minor changes in leakage performance.

Each K-MRC is packaged into a cartridge assembly and configured to meet user requirements for control of gas leakage to process, vent, and atmosphere. Standard offerings include single buffer, single buffer with safety vent, and dual buffer arrangements, but are not limited to these choices.

Features and Benefits

- No catastrophic failure mode

- Tolerates liquid and solid contamination without failure

- Tolerates radial misalignment and vibration without failure

- No limit for axial movement

- Can be configured to meet user requirements for process compatibility, environmental safety, and simplicity of operation

- Bi-directional operation

- Compact, self-contained cartridge

- No large rotating mass, avoiding rotor dynamic issues

- Comparable leakage rates to dry gas face seals

- Expected run time of 40,000hrs+ prior to archbound condition

- Compact size allows for retrofit of most labyrinth seals

- Specialty materials available for low-dewpoint gases

- Split-housing configurations available

- Seal repair kits available to rebuild seal on site

Applications

- Refinery

- Wet gas, coker, alkylation, flare gas recovery, crude unit compressor shaft seals

- Natural gas processing plants

- Propane refrigeration, Ethylene refrigeration, Propylene refrigeration compressor shaft seals

- LNG boil-off and refrigeration compressor shaft seals

- Petrochemical

- Propane refrigeration, styrene off-gas, ammonia refrigeration, acetylene